IS UV CURING POSSIBLE IN WHITE PAINT APPLICATIONS?

The coating process using ultraviolet light energy (UV curing) is a powerful technique used in industries as diverse as automotive, electronics, printing, packaging, medical converting, flooring, furniture and metal pipes and tubes.

UV curing technology is a "clean" technology compared to conventional thermal curing and offers superior economic advantages. High speed curing, minimal space requirements for equipment, low energy consumption, low temperature applications and minimal solvent content of UV cured coatings offer economic and environmental advantages.

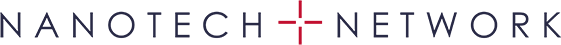

In the case of white paint, the most common pigment is titanium dioxide (TiO2), which is well known to absorb UV light. However, UV curing of white paints containing TiO2 is difficult. Because TiO2 absorbs UV light, the light cannot penetrate into the liquid paint and as a result the paint cures on the top but remains liquid on the bottom. Therefore, UV curing of white TiO2 coating is still a challenge to be overcome.

SUNUM researchers have developed a solution that controls the light path on the white paint, allowing UV light to reach the full thickness of the paint. By utilizing the advantages of nanotechnology, this solution allows the curing process to be carried out without all of the incident light being absorbed by the TiO2. Thanks to this method developed to solve the problem of an industry stakeholder, white color coatings with high coverage can be obtained with an economical and environmentally friendly approach.

New generation Osteoarthritis Treatment: Microneedle Arrays for Regeneration and More

New generation Osteoarthritis Treatment: Microneedle Arrays for Regeneration and More MXene: A Rising Star 2D Material

MXene: A Rising Star 2D Material Smart Window for Efficient Light and Heat Control

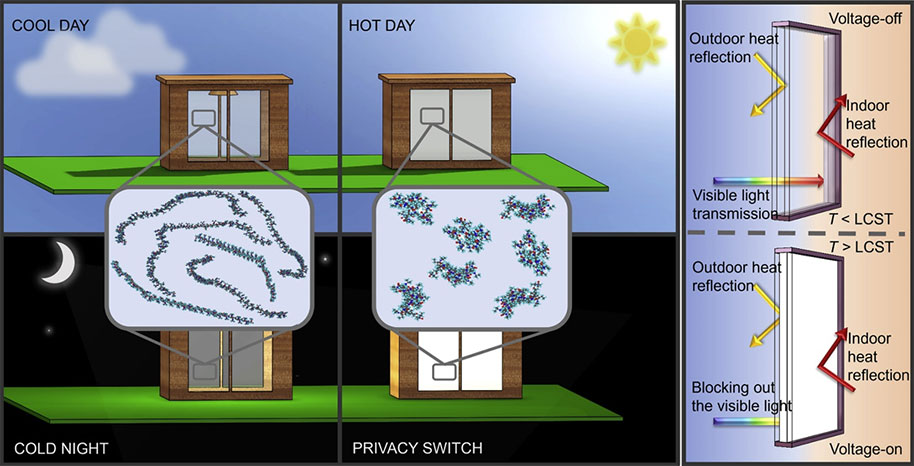

Smart Window for Efficient Light and Heat Control

- 2D Materials

- Agriculture

- Agrochemicals

- Ammonia Gas

- Biomaterials

- Biomedical Applications

- Borophene Focused Ion Beam

- Carbon Nanotube

- Carbon-Based Nanomaterials

- Clean Room

- Coating

- Display Technologies

- DNA Technologies

- EMI Shielding

- Energy Storage

- Energy Technologies

- Fire Retardancy

- Gas Sensor

- Graphene

- Graphene-Based Materials

- Heat Control

- Light Control

- Lithium-ion Batteries

- Metal Nanoparticles

- MXene

- Nanofabrication

- Nanomaterials

- Nanoparticle-Based Gene Carriers

- Nanotechnological Sensors

- Nanotechnology

- Personal Electronics

- Quantum Dots

- Selective Breeding

- Smart Clothing

- Smart Window

- Stretchable Batteries

- Sustainable Crop Production

- Targeted Crop

- Thermochromic

- Transition Metal Carbides

- Transition Metal Carbonitrides

- Transition Metal Nitrides

- Wearable Electronics